OEM Fishing Swivels & Snaps: A Complete Guide for Importers (2025 Edition)

Introduction to OEM Fishing Swivels & Snaps

Fishing may seem simple, but every seasoned angler knows that small components make the biggest difference. Among them, swivels and snaps are indispensable—they prevent line twists, provide quick lure changes, and withstand heavy pulls from powerful fish.

For importers, wholesalers, and brand owners, sourcing OEM fishing swivels & snaps opens the door to tailored solutions. Instead of reselling generic accessories, you can build a line of products that reflect your brand’s standards, appeal to your target market, and offer consistent quality.

What Are Fishing Swivels and Snaps?

Swivels are rotating connectors designed to prevent fishing lines from twisting under strain.

Snaps are clip-like connectors that allow anglers to switch lures quickly.

When combined, they form the widely used snap swivel, a small yet essential accessory in both freshwater and saltwater fishing.

Why OEM Production Matters in Tackle Accessories

The global fishing tackle industry is highly competitive, and many accessories look identical on the surface. OEM production helps importers and brands by:

Offering exclusive designs tailored to regional preferences.

Ensuring consistent quality across bulk shipments.

Improving margins through efficient, large-scale manufacturing.

Benefits of OEM Fishing Swivels & Snaps for Importers

Customization for Different Fishing Markets

Saltwater anglers need corrosion-resistant stainless steel; freshwater anglers may prefer lightweight brass. With OEM production, you can design market-specific products that better serve your customers.

Competitive Pricing and Volume Advantage

OEM suppliers typically offer cost savings on bulk orders, allowing importers to remain price-competitive while improving profit margins.

Quality Assurance and Brand Reputation

High-quality swivels and snaps are critical for anglers. OEM partners with strict QC protocols ensure that every batch meets agreed specifications, helping your brand maintain trust.

Types of Fishing Swivels & Snaps You Can Customize

Barrel Swivels

Simple, affordable, and widely used in general fishing applications.

Ball Bearing Swivels

High-performance swivels that minimize friction, ideal for heavy-duty fishing.

Three-Way Swivels

Designed for advanced rigs, allowing multiple lines to connect.

Snap Swivels

Versatile connectors that combine rotation with quick-change convenience.

Coastlock and Duo-Lock Snaps

Stronger, more secure snaps favored in saltwater and sport fishing markets.

Customization Options for OEM Orders

Materials: Brass, Stainless Steel, or Nickel

Choose the right material for your target market. Stainless steel is stronger and corrosion-resistant, while brass offers affordability.

Coatings and Finishes

Black nickel, polished stainless, or anti-glare finishes can improve both durability and aesthetics.

Strength and Size Variations

OEM suppliers can produce a full range, from ultra-light swivels for panfish to heavy-duty versions for offshore big game fishing.

Packaging and Branding

Custom blister packs, branded boxes, or eco-friendly cartons help boost retail appeal and strengthen brand identity.

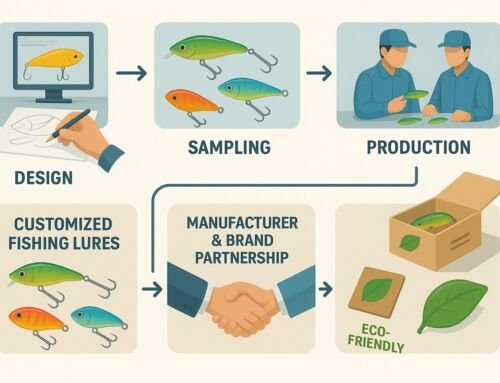

The OEM Manufacturing Process for Swivels & Snaps

Design Consultation and Specification

Importers work with manufacturers to define requirements such as strength rating, snap shape, and finishing.

Prototyping and Strength Testing

Samples are produced and tested for load capacity and durability before mass production begins.

Mass Production and Quality Control

Automated machinery ensures precision cutting, assembly, and finishing, followed by strict QC inspections.

Branding, Packaging, and Shipment

Products are labeled, packaged, and prepared for global shipping according to the importer’s specifications.

Choosing the Right OEM Supplier

Not all manufacturers are created equal. Selecting the right OEM partner for swivels and snaps is essential for building long-term success in your fishing tackle business.

Production Capabilities and Equipment

Look for suppliers with modern machinery and automated processes. This ensures precision, consistency, and the ability to handle large orders without delays.

Quality Control Standards

Reliable OEM partners implement strength testing, corrosion resistance checks, and visual inspections. Importers should request detailed QC reports before approving shipments.

Lead Times and Logistics Support

Time is money. A capable supplier will provide clear production timelines and have experience handling international shipping and customs documentation.

Communication and Service Reliability

Strong partnerships depend on communication. Choose manufacturers who respond promptly, share updates proactively, and provide after-sales support when needed.

Challenges Importers Face with OEM Fishing Hardware

Even with the benefits of OEM production, importers should be aware of potential challenges.

MOQ (Minimum Order Quantity) Issues

Manufacturers often set MOQs to cover production costs. This can be challenging for smaller businesses. Solutions include negotiating phased orders or starting with a limited product range.

Balancing Cost and Durability

Cheaper materials may reduce costs but risk damaging brand reputation. Importers should work closely with suppliers to find the right balance between affordability and long-term performance.

Risk of Product Imitation

In competitive markets, product designs may be copied. To minimize risk, always sign confidentiality agreements (NDAs) and consider registering trademarks or patents.

OEM vs ODM Fishing Swivels & Snaps

OEM (Original Equipment Manufacturing): Importers provide their own designs or specifications, and the manufacturer produces accordingly.

ODM (Original Design Manufacturing): The manufacturer offers ready-made designs that importers can rebrand.

👉 Importers who want unique, branded accessories should consider OEM, while ODM is better for those seeking faster, lower-risk market entry.

Global Market Outlook for Fishing Tackle Accessories (2025)

The fishing accessories market is growing steadily, and importers can benefit from several emerging trends:

Rising Demand for Heavy-Duty Accessories

Sport fishing and offshore markets are expanding, driving demand for stronger, corrosion-resistant swivels and snaps.

Eco-Friendly and Corrosion-Resistant Materials

Sustainability is no longer optional. Importers are increasingly sourcing products made from lead-free alloys, recycled metals, and eco-friendly coatings.

Growth in E-Commerce and Private Label Brands

Online sales channels are fueling the need for private label fishing gear. OEM products enable importers to launch exclusive accessories tailored for e-commerce.

Case Example: Importer Success with OEM Swivels & Snaps

A North American importer once relied on generic fishing hardware but struggled to compete with established brands. By shifting to OEM fishing swivels & snaps, they were able to:

Customize stainless steel snap swivels for saltwater markets.

Launch a private label line with branded packaging.

Improve customer loyalty through higher-quality, durable products.

Within 18 months, the importer expanded distribution to three new countries and doubled sales revenue. This case highlights how OEM partnerships can transform an importer’s competitiveness.

FAQs About OEM Fishing Swivels & Snaps

1. What is the typical MOQ for OEM fishing swivels?

Most manufacturers require MOQs between 5,000–20,000 pieces, depending on design complexity and materials.

2. Can I customize snap shapes and lock styles?

Yes. OEM suppliers can produce coastlock, duo-lock, interlock, and other snap types based on importer requirements.

3. How long does OEM production usually take?

The production timeline ranges from 45 to 90 days, including prototyping, testing, and mass production.

4. Are stainless steel swivels more expensive than brass?

Yes. Stainless steel offers higher durability and corrosion resistance, but brass remains popular for cost-sensitive markets.

5. Can small importers work with OEM suppliers?

It’s possible. Some manufacturers offer flexible MOQ options or starter programs for emerging businesses.

6. How do I ensure my OEM products meet market standards?

Request sample testing reports, certifications, and quality audits before committing to mass orders.

Conclusion: Building Stronger Supply Chains with OEM Swivels & Snaps

For importers and wholesalers, OEM fishing swivels and snaps represent more than just small metal parts—they are essential components that define product reliability, customer trust, and brand reputation.

By partnering with the right OEM supplier, businesses can benefit from customization, scalability, and consistent quality, all while staying ahead of global market trends. Whether your goal is to launch a private label brand, expand into new markets, or strengthen your supply chain, OEM fishing swivels and snaps provide the foundation for sustainable growth in 2025 and beyond.