Fishing Swivels & Snaps — Advantages, Common Pain Points, and Practical Solutions

TL;DR (for busy buyers)

- Why they matter: Swivels reduce line twist; snaps speed up lure changes.

- Main problems: Wrong size, poor materials, added weight changing lure action, inconsistent manufacturing.

- What to do: Specify material (316/304 stainless for saltwater), require tensile / rotation / salt-spray tests, match swivel strength to leader line, prefer micro-snaps for action-sensitive baits.

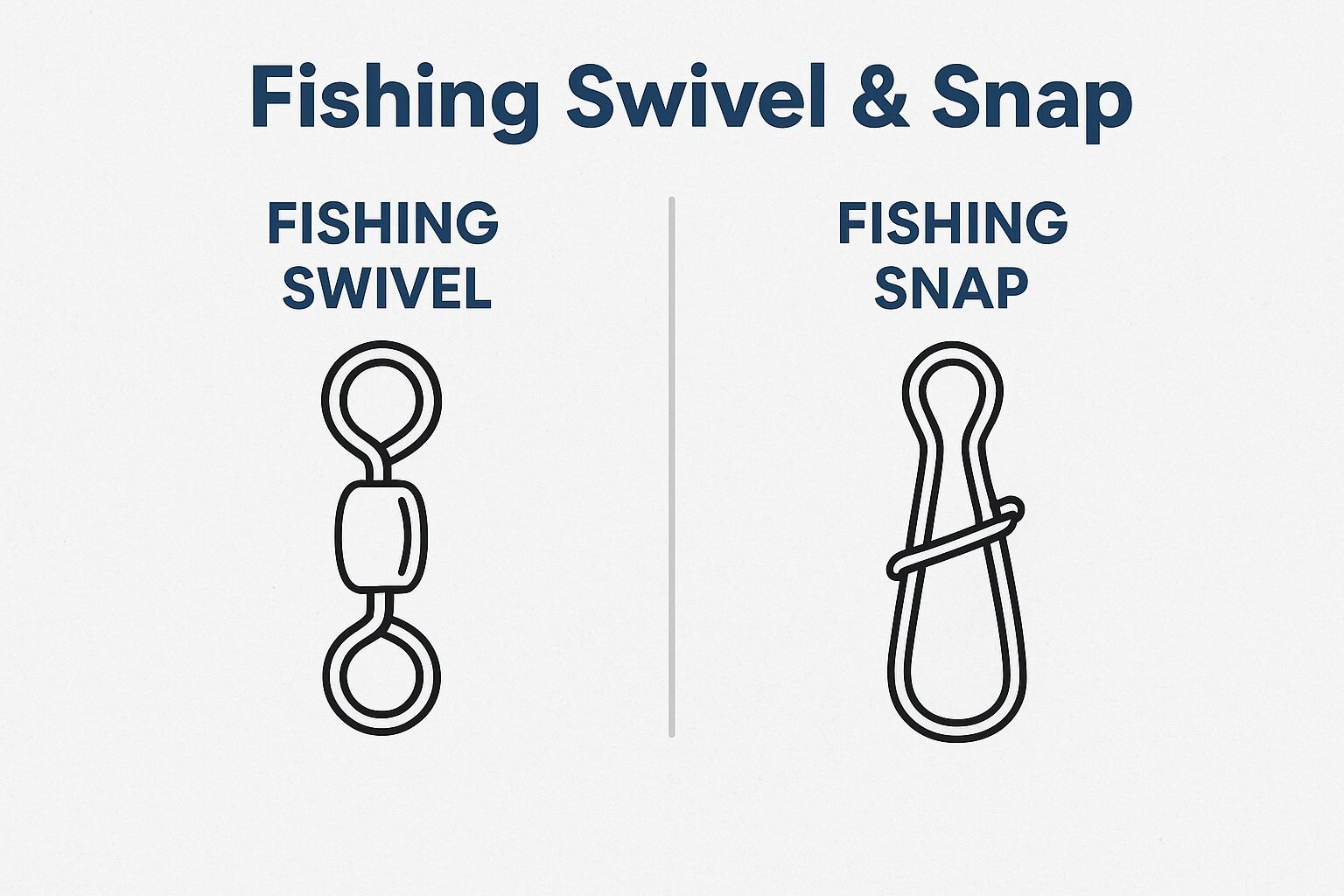

1. What Are Fishing Swivels and Snaps?

Swivel: A small rotating connector placed between mainline and leader to reduce line twist. Barrel, rolling, or ball-bearing types exist; ball-bearing is best for high-spin lures.

Snap: A small clip that allows anglers to change lures quickly without retying. Style and size influence lure action and strength.

2. Advantages

- Reduce line twist: Essential for spoons, spinners, and fast retrieves.

- Faster lure changes: Snaps improve convenience and user satisfaction.

- Product diversification: Premium (sealed ball-bearing, stainless) vs. economy (brass plated) options for multiple markets.

- OEM customization: Logos, plating, and custom snap shapes create brand recognition.

3. Common Pain Points

- Line twist still happens — wrong swivel type or placement.

- Lure action altered — bulky snap + swivel assembly affects action.

- Snaps fail under load — cheap wire or corrosion issues.

- Corrosion in saltwater — brass plated parts tarnish and weaken.

- Inconsistent sizing across brands — leads to confusion and returns.

4. Practical Solutions for Anglers

- Use swivels on spoons/spinners, but tie direct on topwater and soft plastics.

- Choose ball-bearing swivels for continuous rotation; barrel swivels for general use.

- Pick size by strength rating, not just “size number.”

- Use micro snaps to preserve lure action.

- Rinse and dry after saltwater trips; replace corroded or bent snaps immediately.

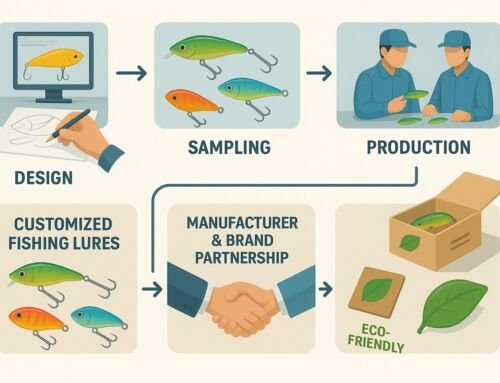

5. OEM & Manufacturer Recommendations

Materials & Finishes

For saltwater, specify 316 stainless steel or 17-4 PH stainless. For freshwater, nickel-plated brass is acceptable but label clearly.

Mechanical Specs & Tests

- Tensile strength test for each batch

- Rotation endurance test for ball-bearing swivels

- Salt spray test for corrosion resistance

- Dimensional control on wire gauge and gaps

- Batch traceability with lot codes

Packaging

Color-coded sizes, clear strength markings, bulk + retail packs available, add maintenance tips on retail packaging.

6. Spec Template Example

Material: 316 stainless steel, fully welded rings Break rating: ≥ 125 lb Snap type: duo-lock / coastlock Tests: tensile, salt spray 48h, 10,000 rotation cycles Packaging: 100 pcs/bag with lot code and desiccant

7. Quick Troubleshooting Table

| Problem | Cause | Solution |

|---|---|---|

| Lure twists | Wrong swivel type | Use ball-bearing swivel |

| Lure action weak | Snap too heavy | Use micro snap or tie direct |

| Snap fails | Poor wire or corrosion | Upgrade to welded stainless snap |

| Rust after trips | Brass plated used in saltwater | Use 316 stainless steel |

8. FAQs

Will a swivel reduce lure action?

Yes, bulky snap + swivel setups may alter lure movement. Use micro snaps or tie direct for sensitive lures.

Do ball-bearing swivels work?

Yes, they rotate smoothly and prevent twist better than barrel swivels.

What is the best material for saltwater?

High-grade stainless steel (316) is recommended for maximum corrosion resistance.

How often should I replace snaps?

Check every trip. Replace if bent, rusted, or loose.

9. Business Value for Brands and Importers

By specifying the right materials and QC standards, you reduce returns, increase customer satisfaction, and strengthen your product line.

10. Partner with Yangzhou Terminalpro Imp. & Exp. Co., Ltd.

We provide OEM & ODM fishing swivels and snaps with strict quality control, saltwater-ready materials, and customized packaging. Whether you are a brand owner, distributor, or importer, we help you deliver reliable, market-ready products worldwide.